PRODUCT > LED Equipment

PRODUCT > LED EquipmentSecondary Battery Equipment

Secondary Battery Equipment

(Automatic feedef, Folding)

- Roll-to-roll type assembly process equipment in automobile/ESS battery manufacturing technology

- Application of unmanned material supply system

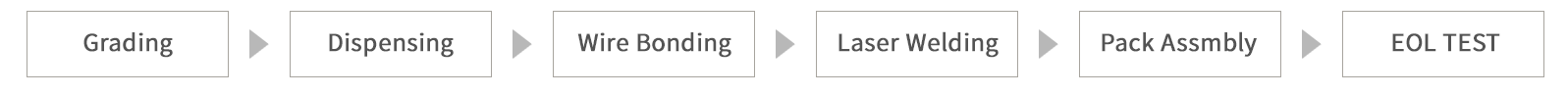

Total solution for battery pack assembly

(Battery Module, Pack Assembly Line)

- Battery Moudle, Pack assembly process equipment in EV (AutoMobile,Bike) Battery manufacturing technology