제품소개 > Secondary Battery Equipment

제품소개 > Secondary Battery EquipmentSecondary Battery Equipment

2차 전지 장비

(자동공급기, Folding)

- 자동차/ ESS 전지 제조 기술에 있어 Roll to Roll Type의 조립 공정

대응 장비 - 무인화 재료 공급 시스템 적용

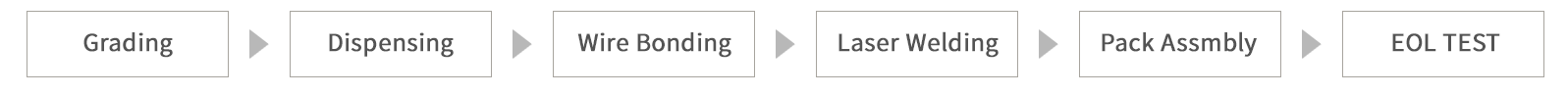

배터리팩 조립 Total Solution 제공

(Battery Module, Pack Assembly Line)

- EV(AutoMobile,Bike) 2차 전지 Battery Module, Pack 조립 공정

대응 장비